CAD -

Computer Aided Design

CAM -

Computer Aided Manufacturing

card-edge connector -

cathode -

1. In an electron tube the electrode

through which a primary source of

electrons enters.

2. The general name for any negative

electrode. 3. When a semiconductor

diode is biased in the forward direction,

that terminal of the diode which is

negative with respect to the other

terminal. 4. In electrolytic plating,

the piece being plated.

CEM-1—A NEMA

grade of industrial laminate having a

substrate of woven glass surfaces over a

cellulose paper core and a resin binder

of epoxy

chip-on-board —Abbreviated

COB. In this technology integrated

circuits are glued and wire-bonded

directly to printed circuit boards

instead of first being packaged. The

electronics for many mass-produced

toys are embedded by this system,

which can be identified by the black

glob of plastic sitting on the board.

Underneath that glob (technical term:

glob top ), is a chip with fine wires

bonded to both it and the landing pads

on the board.

CIM—Computer

Integrated Manufacturing

clad

- generally referring to the

copper film on the surface of the

printed circuit board... features in

'etch' are left after the clad has

been imaged and etched with acid to

remove any undesired copper 'clad'.

Coax -

RG cable, or coax as we know it, was

developed by Bell Laboratories around

WWII. Aircraft radio systems that

required long-wire antennas, as with

long range bombers, needed a method to

route the signal to either the belly

or tail mounted long-wire reels

without radiating within the

fuselage. Bell Labs developed it and

called this new cable

Radio Guide or "RG" cable.

collector—1.

The electrode in a transistor that

'collects' electrons

component -

the basic building block of an

electrical printed circuit. Typical

components are; resistor, capacitor,

diode, inductor, switch, integrated

circuit, lamp, etc.

connector -

a single or multi-pin device

allowing modular disconnection of

electrical assemblies.

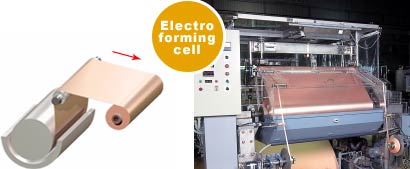

Copper Foil -

The electrodeposited copper foil

starts with the manufacturing process

in which copper dissolved in

electrolyte is electrodeposited on to

the surface of the revolving drum in

the form of a thin foil. In this

manufacturing process, various copper

foils ranging from general printed

wiring boards to sophisticated digital

devices are produced according to

electrolyzing conditions. In the next

process, smoothing and stain-proof

processing are executed to pass

various reliability tests required by

their intended usage. Finally, the

copper foils that pass these tests are

shipped out in rolls or in sheets.

Manufacture of the

original foil ranging in thickness

from 6µm to 175µm, depending on the

usage.

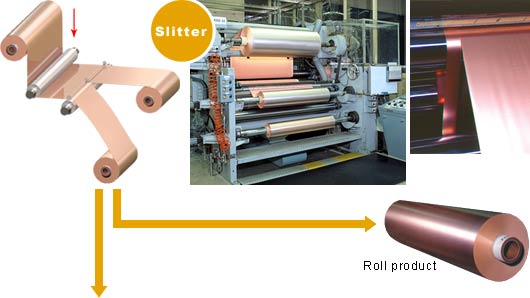

Surface treatment

Slitting

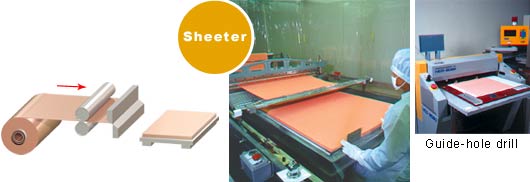

Sheeting

Making sheets from rolls and making

guide-holes for pin lamination

Sheet copper material

Current - The

Movement

of Electrons

through a conductor, 1 Amp = 1 Volt x 1

Ohm

1 AMP = 1 coulomb of

charge per second

See Wikipedia

definition of Current -

http://en.wikipedia.org/wiki/Electric_current