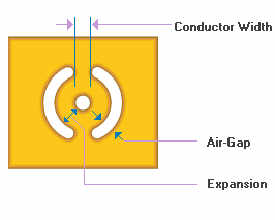

Thermal Relief Pad

- AKA Thermal Ties, Wagon

Wheels, Thermal Webs

Thermal

connections to a plane are described in

MIL-STD-275E paragraph 5.2.5 Thermal

Relief in Conductor Planes

and referenced in Figure 14 'Ground

Plane Lands' in the Appendix. IPC

has since replaced MIL-STD-275 with

IPC-2221 and IPC-2222. There in section

9.1.3 of IPC-2221 you find the same

information as was published in

MIL-STD-275 with a reference to IPC-2222

the 'Sectional standard' for 'more

detailed information'...

Regarding the

IPC-2222 9.1.2 Thermal Relief in

Conductor Planes you will find

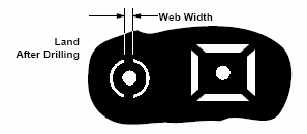

the relationship between the hole size,

land and web area is has a very specific

relationship which they choose to term as

'critical'.

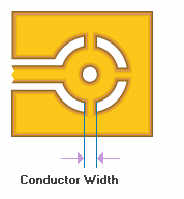

Typically, to calculate

the width of the thermal tie connections

you need to divide the minimum land area

diameter by 60% and then divide that

number by the number of spokes desired to

obtain the width of each thermal

connection trace.

Example:

LAND SIZE CALCULATION

Maximum hole size = 1.0 [0.040]

Annular ring = 2 x 0.13

[0.005] = 0.26 [0.010]

Fabrication allowance = 0.25 [0.010]

Minimum land size = 1.0 [0.040] +

0.26 [0.010] + 0.25 [0.010] = 1.51

[0.060]dia.

THERMAL RELIEF CALCULATION

Total thermal width = 60% of land size

= 0.6 x 1.51

[0.060]

= 0.91 [0.036

ORIGINAL WEB SIZE CALCULATION

2-web width = one-half of total thermal

width

= 0.5 x 0.91 [0.036]

= 0.45 [0.018]

3-web width = one-third of total thermal

width

= 0.33 x 0.91 [0.036]

= 0.30 [0.012]

4-web width = one-fourth total thermal

width

= 0.25 x 0.91 [0.036]

= 0.23 [0.009]

The total

cumulative copper in the spokes for all

layers in any plated thru hole must not

exceed 160 mils or 4.0mm for 1 oz.

copper... 80 mils or 2.0mm for 2oz

copper.

Also you

need to make sure that you do not

restrict the current carrying capacity of

the plated thru hole structure by

removing too much copper.

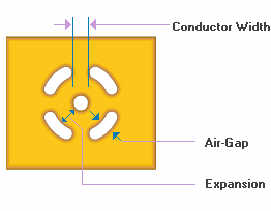

If the land size used in the design is

greater than the minimum value calculated

above, then the percentage difference

between the land diameters must be

subtracted from the total web width

calculation. This balances the

thermal distribution in the pad

compensating for the greater copper

volume in a larger than minimum pad.

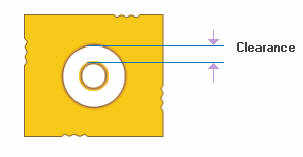

The next consideration is the clearance

area between the land and the copper

plane. Section 9.1.3

Clearance Areas in Planes, points

to an illustration that clearly states

that the clearance area should not be

less than 10 mils or 0.25mm and/or not

less than the electrical spacing

requirement based upon the voltage being

applied to the conductors.