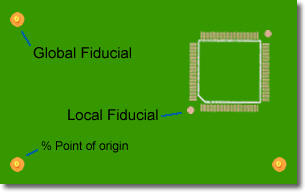

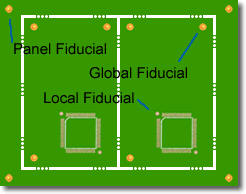

Global Fiducials:

Fiducial marks used to locate the

position of all features on an

individual printed circuit board.

When multiple boards are processed

as a panel, the global fiducials

may also be referred to as panel

fiducials if used to locate the

circuits from the panel datum.

Local Fiducials:

A fiducial mark (or marks) used to

locate the position of an

individual land pattern or

component that may require more

precise location, such as a .020”

pitch QFP.

Image Fiducials:

Global fiducial marks on a multiple

printed circuit board fabrication

panel that are located within the

perimeter of an end-product printed

circuit board.

Panel Fiducials:

Global fiducial marks on a multiple

printed circuit board fabrication

panel that are located outside the

perimeters of the end-product

printed circuit boards.

Flatness:

Board flatness is described in

terms of a deviation from a

theoretical perfectly flatness in

inches square... with the effective

deviation from that datum being

.0075 in per in for surface mount

technology boards. (Through hole

technology allows .0150 in. per in.

deviation). What that means is that

any given square inch of board

surface will not exceed a

difference of .0075 inches in it's

flatness with respect to any

adjacent square inch of board

surface around it. An example of

this would be like the figure shown

below, where we have a board that

is 10 inches wide and is

illustrated in a typical arc at the

extreme bow or warp that still

would pass under the .0075 in. per

in. rule. The total deviation for

the board at it's center is only

.0375 inches from edge to center

assuming the maximum allowable

deviation inch per inch across it's

surface from end to end.

For the specification regarding

testing for surface flatness see

IPC-TM-650 Method

2.4.22.

http://www.ipc.org/4.0_Knowledge/4.1_Standards/test/2.4.22c.pdf